How a Sydney engraver modernised industrial signage production with Canon’s Arizona technology

For more than two decades, Elanora Signs & Engraving has been a trusted name in industrial signage across New South Wales. The family-run business, led by Stephen Macquarie, built its reputation on craftsmanship, specialising in tool engraving into stainless steel for industrial applications. Today, thanks to Canon’s Arizona flatbed printing technology, the business has evolved into a highly efficient, multi-technology signage producer combining engraving, laser cutting, and direct-to-substrate printing—all under one roof.

From Traditional Engraving to Advanced Flatbed Printing

Elanora Signs’ move into digital printing began a decade ago when Stephen recognised the need to meet his clients’ growing demands for faster turnaround and more flexible production.

“Many of our clients wanted durable signage delivered quickly,” explains Stephen. “Traditional engraving and screen printing methods couldn’t always meet those timeframes, especially for one-off or low-volume jobs.”

The solution came with the company’s first Canon Arizona flatbed printer, which revolutionised its production process. By printing directly onto metal substrates—such as satin anodised aluminium or 1 mm white aluminium—Elanora Signs eliminated the need for printing on vinyl and laminating, reducing waste and streamlining workflow.

“Now we print directly onto the sheet, cut it straight up, and it’s ready to go,” says Stephen. “The Arizona handles full-size sheets perfectly, and the vacuum system keeps everything stable for precision printing. It has completely changed how we operate.”

Smarter, Faster, and More Sustainable with the Arizona 135 GT

The company’s most recent upgrade to the Arizona 135 GT was a natural next step. According to Stephen, the decision was driven by speed, sustainability, and quality improvements.

“The LED curing system was a game changer,” he says. “Our previous models used halide lamps that took time to warm up and needed replacement. Now, with instant-on LED curing, we can start printing straight away, save energy, and reduce downtime.”

Stephen also highlights the automatic cleaning station as one of the printer’s standout features.

“It’s so much faster than before and keeps the heads in perfect condition. Once you get into the routine, maintenance is minimal, and print consistency is excellent.”

Bringing All Technologies Together

Bringing All Technologies Together

A key strength of Elanora Signs is its ability to combine engraving, laser cutting, and flatbed printing to deliver complete solutions in-house. This integration allows the team to complete even complex jobs on tight deadlines.

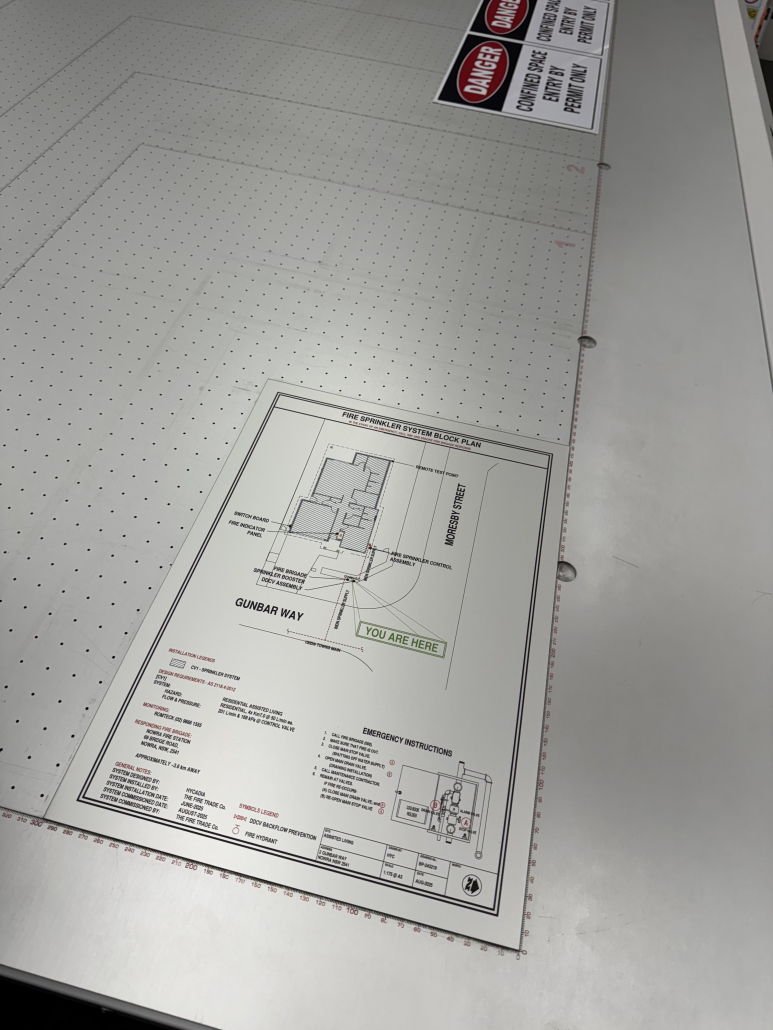

“For example, we can engrave a panel, print directly into the engraving using the Arizona’s vacuum table, and produce a durable, precise result that lasts far longer than paint,” says Stephen. “We also print intricate block plans and switch plates for the electrical and fire industries—fine detail, sharp colours, and excellent outdoor durability.”

This versatility enables the company to respond quickly to clients’ needs, often completing orders on the same day.

A Partnership Built on Trust

Behind the technology is a strong partnership. Stephen speaks highly of the long-standing relationship with Canon Production Printing Australia.

“Having faith in the service department is a big thing,” he says. “We’ve worked with the same support team for years, and every installation has gone smoothly. The service team and software specialists are always available and ready to help. That continuity makes a huge difference to a small business like ours.”

Sustainability and the Future

Sustainability has become an increasing focus for Elanora Signs & Engraving, especially working with large international clients that have strict environmental compliance standards. “The Arizona’s LED curing and direct-to-material printing reduce waste, energy use, and the need for adhesives,” Stephen notes. “It aligns perfectly with our clients’ sustainability requirements and with how we want to run our business.” As the business transitions to the next generation of the Macquarie family, Stephen is confident Canon will continue to play a central role. “I can’t see our model changing,” he says. “We’ll continue to invest in the Arizona range—it just works for what we do.”

Canon’s Perspective

“Elanora Signs & Engraving is a great example of how a specialised business can evolve through smart technology investment,” says Steven Badger, Head of Sales & Professional Services, Canon Production Printing Australia.

“The Arizona 135 GT enables them to maintain their traditional craftsmanship while achieving faster turnaround, improved sustainability, and consistent quality. It’s a perfect demonstration of how digital printing complements and enhances established production techniques.”

Key Benefits of the Arizona 135 GT for Elanora Signs

- Direct-to-metal printing with no vinyl or lamination

- Instant-on LED curing for faster, energy-efficient production

- Automatic cleaning station for reduced maintenance

- High adhesion and colour durability on stainless steel and aluminium

- Integrated workflow with engraving and laser cutting for complete in-house control